Chilling

Refrigeration extends the shelf life of breadfruit, 12 to 13°C being optimal. Domestic and home refrigerators are normally set to operate at 4oC, but the temperature can be adjusted to optimal if the sole/main purpose is breadfruit storage. At these temperatures the life of the breadfruit is doubled for every 10oC drop in temperature. If the harvest temperature is 35oC then at 25oC the breadfruit will last twice as long and at 15oC four times as long and so on. However below 8oC breadfruit suffers chill damage and deteriorates very rapidly. Shelf life can be further extended if the fruit is wrapped. Plastic can be used but there is the possibility that condensation would form on the inside of the plastic wrappers which would accelerate rot. Paper wrapping is a less risky and an environmentally-friendly alternative.

“Does chilling stop deterioration?”

Chilling/cooling only slows deterioration – it does not stop it. Therefore chilling is a procedure used to maintain fruit quality when there is a delay in delivering freshly harvested fruit to the customer. In recent work in Samoa, postharvest experiments have shown that the maximum storage life for the variety puou was 11 days and 16 days for ma’afala fruit based on 17°C cool storage. The only equipment needed for chilling is a large refrigerator.

Freezing

“What is involved if I want to sell frozen breadfruit?”

Freezing is an expensive process and it is important to remove inedible portions of the fruit. Hence before freezing, ripe breadfruits are washed, peeled and cut into convenient sections (often decided by the pack size or the market specifications) with any seeds removed. The breadfruit must be delivered to the processor in the best possible condition; any delays will see a breakdown in the breadfruit texture. The washed, peeled and cut breadfruit is then packaged and frozen (Figure 3). It is important to package frozen food in (at least) 50 micron polypropylene (your supplier will help). Packaging choice depends on the shelf expected shelf life of the product. If two days shelf life is required (say for the local school or a fete) then polythene will do. For up to 6-8 weeks 50 microns thickness of polypropylene is required. For shelf life beyond 8 weeks five component composite is required (as exemplified by the commercial crisp and snack food market). Foods dry out in the freezer and also some flavours can migrate from one food to another causing ‘taint.’ Domestic home freezers are suitable for small scale processing. Chest freezers are preferred because less ambient/warm air enters the freezer as they are opened and closed.

For formal markets and export the storage temperature must remain below minus 18oC. Some SMEs are now freezing to the first stage and immediately transported to larger organisations to reach international standards which at a minimum are those mandated by Codex Alimentarius or national specifications such as Food Standards Australia and New Zealand (FSANZ).

The quality of frozen foods once they are thawed depends on the rate at which they are frozen. It is important to cool through the range of temperature of minus 0.5°C to minus 5.5°C as quickly as possible since this causes least damage to the food structure. To achieve this, blast freezers are used as they blow very cold air across the food at very high speed; commercial processing operations use large scale blast freezers. These freezers are very expensive and the cost can only be justified if there is a sufficient supply of breadfruit available, or other complementary products, to enable the freezers to operate for eight hours per day for five days a week.

Figure 3 Frozen breadfruit wedges ready for dispatch

Currently breadfruit supplies are unable to meet this requirement therefore processors use large-scale blast freezers for freezing all starchy staples and for breadfruit when supplies are available.

For successful marketing the frozen or cold chain must be in place from the point of manufacture to the point of sale. This means there must be refrigeration at minus 18°C at the processing point, during distribution (refrigerated trucks) and at the retail outlet. Instructions on labels must include ‘Store at minus 18°C’ and ’Do not refreeze after thawing.’

Drying

A large surface area is important for drying so slicing the breadfruit is the first step in the drying process; this enables the water to be removed through the surface more efficiently. Breadfruit pieces can be dried in the sun (Fig. 4), in a low temperature oven (50˚C) or in a dehydrator.

Several types of solar dryers exist, including active and passive dryers; tent, box or cabinet designs; and backup heating designs. The latter are often referred to as hybrid designs providing the option of fuelled heating (preferably a small wood-fired stove or else propane or kerosene heater) placed in the drying cabinet below the shelves of fruit. The moisture content of fresh breadfruit is approximately 20% (+/-2%) – the moisture content must be below 4% for stability drying resulting in a loss of 16%. The Trees that Feed Foundation have calculated that using their hybrid solar dryer 50 kg of fresh fruit will yield approximately 15 kg of dried fruit in a day, or approximately 300 kg per month.

Several types of solar dryers exist, including active and passive dryers; tent, box or cabinet designs; and backup heating designs. The latter are often referred to as hybrid designs providing the option of fuelled heating (preferably a small wood-fired stove or else propane or kerosene heater) placed in the drying cabinet below the shelves of fruit. The moisture content of fresh breadfruit is approximately 20% (+/-2%) – the moisture content must be below 4% for stability drying resulting in a loss of 16%. The Trees that Feed Foundation have calculated that using their hybrid solar dryer 50 kg of fresh fruit will yield approximately 15 kg of dried fruit in a day, or approximately 300 kg per month.

“If I live somewhere with high humidity, should I not consider drying?”

Drying efficiency depends on the relative humidity of the air around the slices. If the relative humidity is near 100% then condensation will settle on all surfaces. Air with a humidity of less than 40% is very suitable for sun drying. Without fans it is rarely possible to control air circulation around the breadfruit and if the humidity rises then the breadfruit will not dry sufficiently and mould will become a problem. Processors living in areas of high humidity must expect that drying will be prolonged (unless they have invested in efficient solar/biomass or electric driers) and sometimes difficult to achieve before the fruit supports mould growth. It is possible to dry in any climate but the cost is always higher in high humidity environments – the drier/leeward side of large Pacific islands and some low-rainfall atolls will better support efficient drying.

Where rainfall cannot be predicted, the process must be more controlled. In this case the drying chamber is enclosed and air that is not adequately dry for sufficient water removal, is heated (Fig. 5) Air with high humidity will expand during heating and thus its capacity to absorb water from the breadfruit is enhanced so heated air is commonly used for drying foods.

Where rainfall cannot be predicted, the process must be more controlled. In this case the drying chamber is enclosed and air that is not adequately dry for sufficient water removal, is heated (Fig. 5) Air with high humidity will expand during heating and thus its capacity to absorb water from the breadfruit is enhanced so heated air is commonly used for drying foods.

The moisture (water) content of drying chips should be monitored and should be below 7-8% at conclusion of the drying process. In the absence of moisture meters then you should aim for slices that are brittle and crisp (Fig. 6). For packaging, polypropylene 50 microns thick would be sufficient to prevent softening of the dried breadfruit product provided that the product is stored in a cool dry place.

Figure 6 Dried slices of breadfruit |

Figure 7: Restaurant size coffee grinder for producing flour |

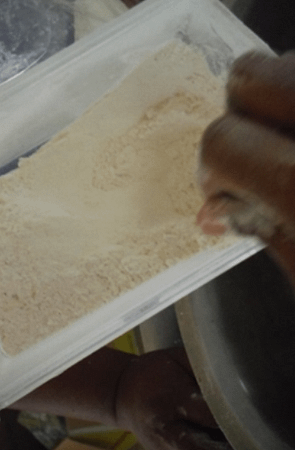

Figure 8: Breadfruit flour |

Dried breadfruit slices have a number of uses, such as in soups, casseroles and in puddings. The final pulverising stage is very simple and just an add-on to what is a fairly complex drying procedure. For breadfruit ‘flour,’ the dried slices are simply ground up either by hand or using a mill ranging in size from a domestic coffee grinder (Fig. 7) to a large flour mill.

Some baked goods can be produced using 100% breadfruit flour (Fig. 10) however breadfruit flour (Fig. 8) does not contain gluten so it does not behave like wheat flour. It can be used as a partial replacement for wheat flour by adding up to 30% of the weight of breadfruit flour to wheat flour (Fig. 9).

The baked products so produced have a heavier but pleasant texture and have the advantage that the products satisfy hunger for longer periods.

Figure 9: Bread and buns made from 30% breadfruit flour (mixed with wheat flour) at the Tutu Rural Training Centre Figure 9: Bread and buns made from 30% breadfruit flour (mixed with wheat flour) at the Tutu Rural Training Centre |

Figure 10: ‘Babakau’ made from 100% Tutu breadfruit flour Figure 10: ‘Babakau’ made from 100% Tutu breadfruit flour |

Traditional sun drying is a long process and problematic in countries where there is consistently high humidity. A successful alternative is simply to use cooked, mashed breadfruit that can be added to dough. Successful bread has been made from two-thirds flour dough with one-third breadfruit mash. This sidesteps the need to dry the breadfruit into a powder.

The significant advantage that breadfruit flour has over other starch-based commodities is gelling properties. It disperses almost instantly in cold water and does not clump. It is a perfect gluten-free base of instant soups and sauces and is a direct gluten-free replacer for corn flour (Fig. 11). Breadfruit flour therefore has enormous potential as a gluten-free thickener in products such as blancmange, gravy thickener and instant pudding (Fig. 12), but this level of value-adding is still mostly in the research stage.